Last month, Manel our Product Manager went on his third trip to the Pearl River Delta. Shenzhen, China.

His first trip was in July 2017, where he went with Matt and Luis to do the preliminary visits to the factories.

The second trip was in January of this year, where this time Manel went alone to meet with viable manufacturing partners.

As the delivery date of the Raise keyboard quickly approaches, it was essential that Manel visited the factories to ensure that everything was going as planned.

He met with our partners and personally oversaw the developments of the different components of the Raise:

· Cables

· Palm pads

· Keycaps

· Packaging

Cables

As we are creating custom cables for the Raise, there are a few aspects that we wanted to make sure the factories got right. The cable will be braided and will have an aluminium enclosure for the connector. There will also be a strong plastic case protecting the cable and the enclosure.

The cable samples that they showed us were close to what we envisioned. But there are still a few things that need iteration.

Logos

We’ve been thinking of having our logo in the cables but we’re still unsure about this. We’ve asked our manufacturers to send us some samples.

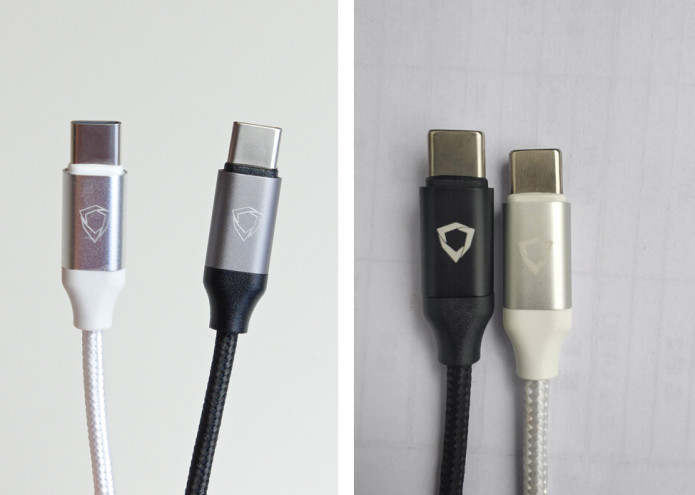

[caption id="" align="aligncenter" width="600"] Sample 1 and Sample 2 of the logos[/caption]

Sample 1 and Sample 2 of the logos[/caption]

This logos are still not how we want them to look. The size and location are correct but the separation between the 3 elements of the logo is too small.

We’re still working with the manufacturers to get another iteration.

Matte aluminium enclosure

The enclosure of the cable is aluminium and we are offering them in silver and black.

The first sample that we received had a shiny finishing. But we spoke with the manufacturers and told them that we would like it to have a matte finishing, which you can see on the image on the right.

[caption id="" align="aligncenter" width="599"] Cable with shiny finishing vs Cable with matte finishing[/caption]

Cable with shiny finishing vs Cable with matte finishing[/caption]

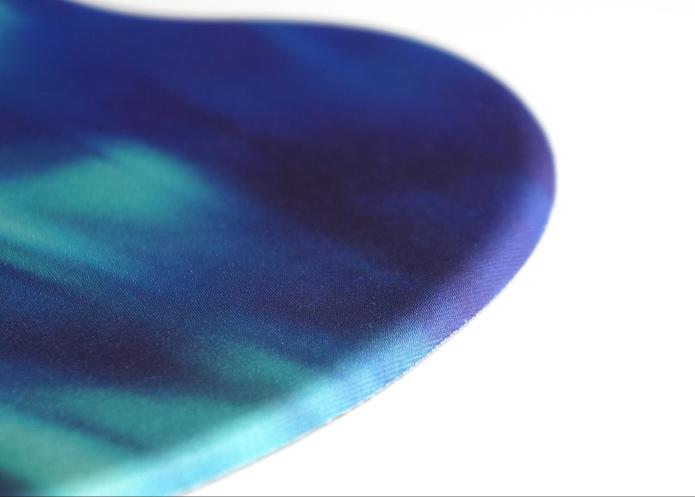

Grey matte braided cable

We want the consistency of the matte to also be seen in the braided cables.

Shown in the image above is the matte finish that we are looking for. But the color isn't what we want. The cable color will be light grey, similar to the previous one but without the shiny effect.

Construction

All details needed to be thoroughly checked. The construction of the metal and plastic casing wasn’t as good as we expected.

So we have asked them to improve this build. It is important for us that a detail as small as this has to be perfect.

[caption id="" align="aligncenter" width="600"] Before[/caption][caption id="" align="aligncenter" width="600"]

Before[/caption][caption id="" align="aligncenter" width="600"] After[/caption]

After[/caption]

Palm pads

Anti-slip material for the bottom

We had 2 options for the anti-slip material (the bottom part) of the palm pads: PU (Polyurethane) and rubber

[caption id="" align="aligncenter" width="600"] PU vs rubber[/caption]

PU vs rubber[/caption]

Initially, we wanted to use rubber. The advantage is that it looks more elegant. The disadvantage is that we can’t have it with curved edges because this would require it to be sewn, and we don’t want anything to be sewn. Having sewn edges can give extra pressure in the palms and might cause a bit of discomfort.

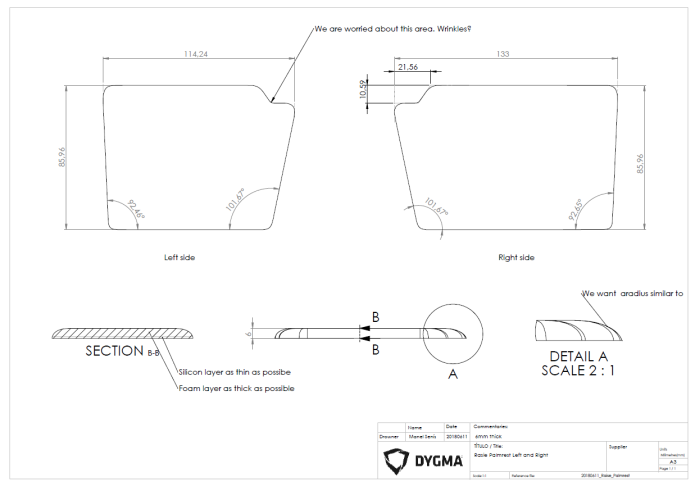

What we want is a simple curved edge as shown in the image below.

[caption id="" align="aligncenter" width="600"] Curved edge[/caption]

Curved edge[/caption]

So we decided to use PU for the bottom part of the palm pads. In between the bottom and the top material will be silicone.

[caption id="" align="aligncenter" width="600"] PU material at the bottom[/caption]

PU material at the bottom[/caption]

Top material

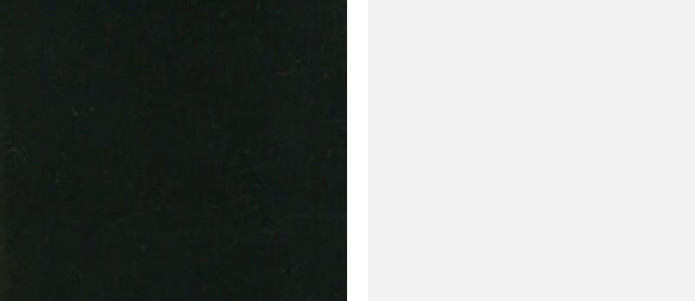

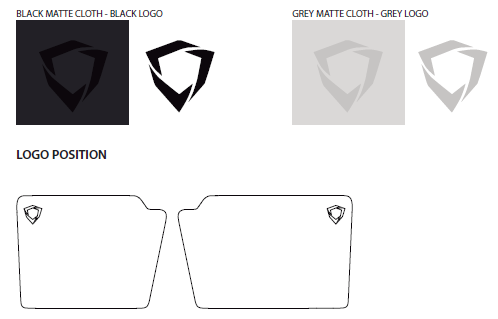

The top material will be a cloth fabric. There will be 2 versions: Black Matte for the black Raise and Pantone Cool Grey 1 for the silver Raise.

[caption id="" align="aligncenter" width="600"] Black Matte and Pantone Cool Grey 1[/caption]

Black Matte and Pantone Cool Grey 1[/caption]

Thickness

The thickness of the palm pads will be a total of 6-millimeter: 1.5mm of the anti-clip PU material and the rest would be the silicone. The cloth fabric will be a very thin layer.

Below you can see a sketch of the dimensions of the palm pads.

Logo

The questions we had regarding a logo were if we needed one, and if so, what would the color be, and where would it be placed?

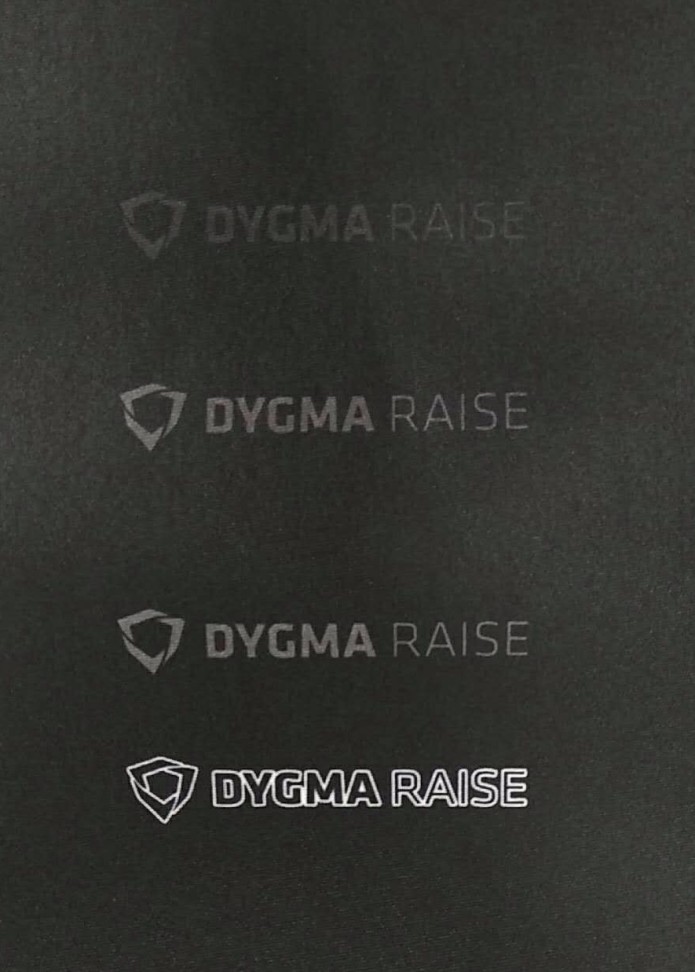

Our idea for the logo is to have it slightly darker than the fabric color so it will look more subtle. In the black matte cloth, the logo will be black. In the Cool Grey 1 cloth, the logo will be Cool Grey 2.

We decided to add text alongside the logo. These were the examples that were sent to us.

We’ve decided to go with the darkest version at the top. We made a prototype of the palm pads to make sure that we’ve pick the best looking solution.

Prototype palm pad logo[/caption]

Prototype palm pad logo[/caption]

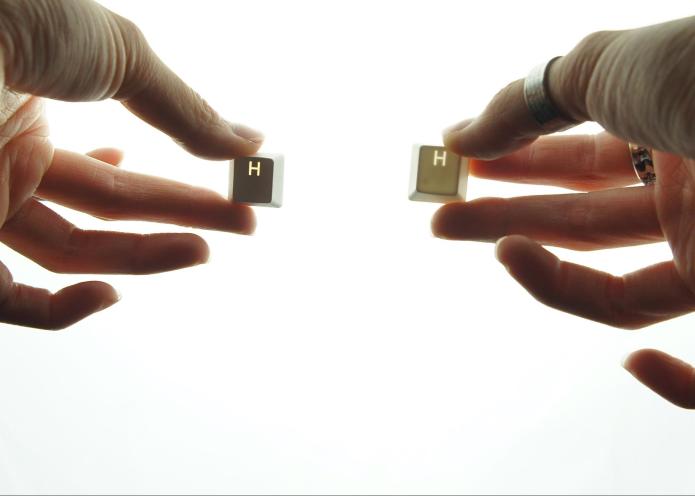

Keycaps

White PBT keycaps

Before the trip to Shenzhen, we were sent samples of different keycap sets from various factories. We inspected them and decided which ones we liked.

In the image above, we decided to go with the keycap on the left.

Manel visited the factory of the manufacturer that we favoured. He assessed the keycaps and learned that the white keycaps are very delicate. They are more difficult to make thus are more expensive.

At present, we haven’t reached the minimum order quantity for the white keycaps. This means that we will be paying more for them to be made. And since the white keycaps are more costly than the black, we are hoping that we reach the minimum order quantity soon.

So if you guys want to make an additional order on the white keycaps, be our guest!

ABS keycaps

When Manel checked the ABS keycap samples, he saw that there was a problem with the surface quality of the paint and quickly brought it up with the manufacturers. It was an easy fix. Although the PBT keycaps are clearly of higher quality, the quality of the ABS keycaps were good enough as well.

The Raise is offered in seven different keycap languages.

The US English and UK English keycaps will be made of PBT.

But the rest of the keycaps, German, French, Spanish, Nordic, Japanese, and Blank keys, will be made of ABS. With only a few orders of the other languages, we weren’t able to reach the minimum order quantity for them to be PBT. We also weren’t able to reach the minimum order quantity for the double injection ABS. So, these ABS keycaps will have to be be laser etched.

Packaging

We did a few updates on our concepts for the packaging. You can check them here. We were initially thinking of sending the keyboard with separate boxes for the switches and keycaps, and the user assembles the keyboard himself.

This was an interesting concept that we might push in the future. But as for our pre-orders, the Raise keyboard will come assembled.

We are also going to make an extra PET case for the extra keycaps. They will be in a different envelope.

Thanks for reading guys!

If you have any queries, don’t hesitate to message us in any of our social media accounts: Instagram, Twitter, Youtube, Facebook, or in the comments below.

This post is the third of the Shenzhen trip series. Read more at:

Last month, Manel our Product Manager went on his third trip to the Pearl River Delta. Shenzhen, China.

His first trip was in July 2017, where he went with Matt and Luis to do the preliminary visits to the factories.

The second trip was in January of this year, where this time Manel went alone to meet with viable manufacturing partners.

As the delivery date of the Raise keyboard quickly approaches, it was essential that Manel visited the factories to ensure that everything was going as planned.

He met with our partners and personally oversaw the developments of the different components of the Raise:

Cables

As we are creating custom cables for the Raise, there are a few aspects that we wanted to make sure the factories got right. The cable will be braided and will have an aluminium enclosure for the connector. There will also be a strong plastic case protecting the cable and the enclosure.

The cable samples that they showed us were close to what we envisioned. But there are still a few things that need iteration.

Logos

We’ve been thinking of having our logo in the cables but we’re still unsure about this. We’ve asked our manufacturers to send us some samples.

This logos are still not how we want them to look. The size and location are correct but the separation between the 3 elements of the logo is too small.

We’re still working with the manufacturers to get another iteration.

Matte aluminium enclosure

The enclosure of the cable is aluminium and we are offering them in silver and black.

The first sample that we received had a shiny finishing. But we spoke with the manufacturers and told them that we would like it to have a matte finishing, which you can see on the image on the right.

Grey matte braided cable

We want the consistency of the matte to also be seen in the braided cables.

Shown in the image above is the matte finish that we are looking for. But the color isn’t what we want. The cable color will be light grey, similar to the previous one but without the shiny effect.

Construction

All details needed to be thoroughly checked. The construction of the metal and plastic casing wasn’t as good as we expected.

So we have asked them to improve this build. It is important for us that a detail as small as this has to be perfect.

Before

After

Palm pads

Anti-slip material for the bottom

We had 2 options for the anti-slip material (the bottom part) of the palm pads: PU (Polyurethane) and rubber

Initially, we wanted to use rubber. The advantage is that it looks more elegant. The disadvantage is that we can’t have it with curved edges because this would require it to be sewn, and we don’t want anything to be sewn. Having sewn edges can give extra pressure in the palms and might cause a bit of discomfort.

What we want is a simple curved edge as shown in the image below.

So we decided to use PU for the bottom part of the palm pads. In between the bottom and the top material will be silicone.

Top material

The top material will be a cloth fabric. There will be 2 versions: Black Matte for the black Raise and Pantone Cool Grey 1 for the silver Raise.

Thickness

The thickness of the palm pads will be a total of 6-millimeter: 1.5mm of the anti-clip PU material and the rest would be the silicone. The cloth fabric will be a very thin layer.

Below you can see a sketch of the dimensions of the palm pads.

Logo

The questions we had regarding a logo were if we needed one, and if so, what would the color be, and where would it be placed?

Our idea for the logo is to have it slightly darker than the fabric color so it will look more subtle. In the black matte cloth, the logo will be black. In the Cool Grey 1 cloth, the logo will be Cool Grey 2.

We decided to add text alongside the logo. These were the examples that were sent to us.

We’ve decided to go with the darkest version at the top. We made a prototype of the palm pads to make sure that we’ve pick the best looking solution.

Keycaps

White PBT keycaps

Before the trip to Shenzhen, we were sent samples of different keycap sets from various factories. We inspected them and decided which ones we liked.

In the image above, we decided to go with the keycap on the left.

Manel visited the factory of the manufacturer that we favoured. He assessed the keycaps and learned that the white keycaps are very delicate. They are more difficult to make thus are more expensive.

At present, we haven’t reached the minimum order quantity for the white keycaps. This means that we will be paying more for them to be made. And since the white keycaps are more costly than the black, we are hoping that we reach the minimum order quantity soon.

ABS keycaps

When Manel checked the ABS keycap samples, he saw that there was a problem with the surface quality of the paint and quickly brought it up with the manufacturers. It was an easy fix. Although the PBT keycaps are clearly of higher quality, the quality of the ABS keycaps were good enough as well.

The Raise is offered in seven different keycap languages.

The US English and UK English keycaps will be made of PBT.

But the rest of the keycaps, German, French, Spanish, Nordic, Japanese, and Blank keys, will be made of ABS. With only a few orders of the other languages, we weren’t able to reach the minimum order quantity for them to be PBT. We also weren’t able to reach the minimum order quantity for the double injection ABS. So, these ABS keycaps will have to be be laser etched.

Packaging

We did a few updates on our concepts for the packaging. You can check them here. We were initially thinking of sending the keyboard with separate boxes for the switches and keycaps, and the user assembles the keyboard himself.

This was an interesting concept that we might push in the future. But as for our pre-orders, the Raise keyboard will come assembled.

We are also going to make an extra PET case for the extra keycaps. They will be in a different envelope.

Thanks for reading guys!

FOLLOW US (AND DON’T MISS ANY OF OUR AWESOME CONTENT!)

Youtube