Are we there yet?

Believe us when we say that we can’t wait for mass production just as much as you guys! It’s been long and arduous but the learnings we’ve had throughout this entire process have been valuable.

As we approach this final leg (that has been taking weeks), we first want to thank all of you guys who’ve stuck it out with us. Some of you, who have graciously left positive comments giving their moral support, have really helped us keep our heads high to push through. For those who’ve chosen to support us in silence - thank you!

We understand that this project has taken longer than expected, thus the refunds were inevitable. But still, we’re very glad that we got the opportunity to bring about this wonderful community!

And because of all of your patience with us, we decided to give each and every one of you something special along with your Dygma Raise keyboard. We know the wait has been painstaking so we hope this special gift can make up for it.

We won’t divulge any more information, but hope the surprise will be enough ??

So, that’s all for the sappy intro.

Now for the manufacturing updates...

In the last update, we talked about the remaining components that needed to be finalized. Well, most of them are now in the T-off. T-off means that they have been finalized and cleared for mass production.

These components are:

✅ Base

We added ribs to make the structure of the base more resistant and sturdy.

To fix the issue we had with the dark spots, we added small holes beside the screws so that the light would diffuse more evenly.

Another thing we adjusted was the housing for the magnets at the back. In order for the sensors in the PCB to work properly and detect the keyboard’s connection, the magnets needed to be at a certain height. So we added a 1.1mm rib as shown in the photo below.

If you want to learn how the sensor works to detect the keyboards’ connection, check Matt’s video 👇

Lastly, we’ve done the final touches on the base such as the inscription of Dygma Raise and the date of injection.

✅ Joint metal covers

Joint metal covers are ready to go!

✅ Mylar

We have the final sample of the Mylar (the bottom panel) with our Dygma Raise logo and it looks awesome!

✅ Top Panel

The top panel is already done and ready to go. But there was one aesthetic issue we wanted to test with people, and it had to do with the 0.2mm gap in between the two sides when attached.

When we asked a few people what they thought about it, they said they preferred not to see a gap in between the 2 sides.

So we are thinking of doing this modification and remove the 0.2mm gap for mass production. But overall, the top panel is done!

✅ Metal Pins

✅ Special keycaps

The metal pins and special keycaps are also ready to go!

And these are the last components that we are still working on:

⚠️ Palm Pads

Our supplier is still working on getting the shape of the palm pads correct. There was a bit of an issue with the anti-slip material. In the end, we will use the original anti-slip which is not the sticky one. We are now waiting for the final samples but this isn’t delaying anything and they can be easily produced for mass production.

⚠️ Electronics

This is the component we are struggling with at the moment and is the one causing the delay. We weren’t able to pass the EMI pre-certification for CE. We thought that we already found the solution but it failed once more during Matt’s trip last week.

This a major setback for us. Matt has been working everyday trying to figure out the reason why it keeps failing. This has been hard for a few reasons:

- The way the components are placed on the PCB can have an effect on performance, and this means to make a new test we have design and then wait for a new PCB.

- The test equipment is expensive and requires a big room, so we have to hire the space and wait for availability.

- It’s been difficult to work out exactly where the problem areas are in the limited time we have in the test room.

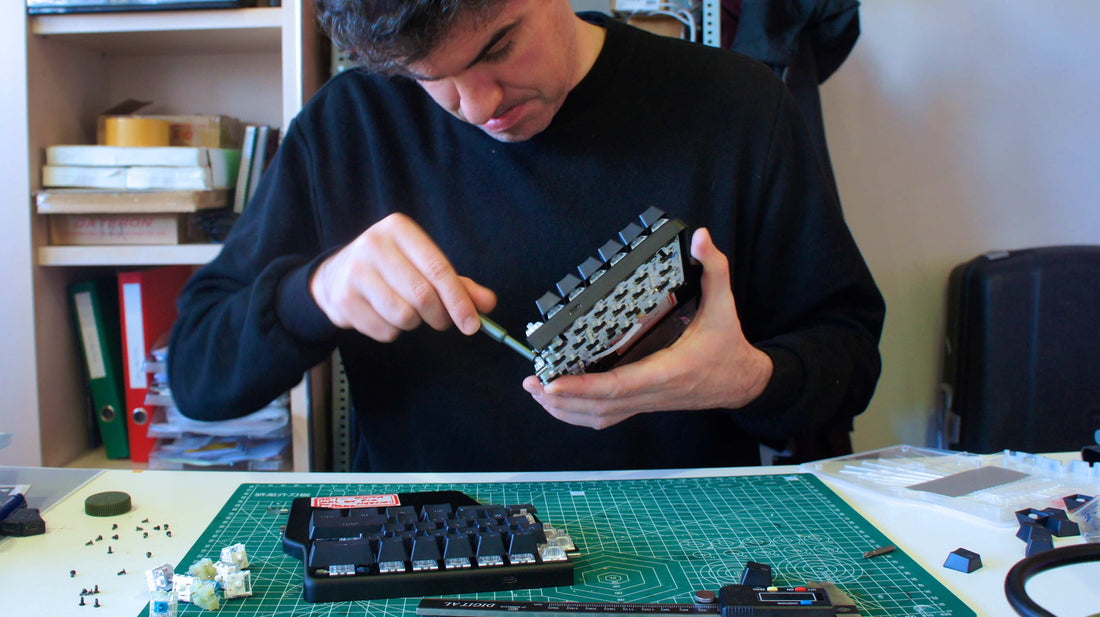

Matt finally had a breakthrough when he found that the noise that was previously thought to have been from the microchip’s clock was actually a result of the LED driver. We’re now testing filtering the outputs of the LED driver to reduce this noise. A new board design is underway.

Hopefully, we will fix this soon and begin the DVT as planned!

If you have questions or concerns, please let us know in the comments below. As always we are open to hear your feedback.

Q&A with Manel Senís

Last week, we published a Q&A video with Manel, our Product Manager. We asked the community on Instagram (@dygmalab) if they had any questions for Manel.

These were their questions and Manel’s answers.

If you have any more questions you’d like to ask Manel or anyone in our team, write it down below! We’d be more than happy to make another Q&A video with your questions.

We hope you guys enjoyed this update! We are hoping that the next one will be about launching the DVT and the start of mass production!

Love,

Dygma Team