The mass production process is ongoing and so far so good!

Here are the latest updates👇

PCBA - Printed Circuit Board

PCBA is in full swing. All the PCB of the Neurons, the left and right low-profile boards, and left main boards have been assembled. What about the right sides I hear you say?

During the testing of the right-side PCBs, we encountered an issue that would have caused a big delay had we not have the right quality testing procedures.

The magnet sensors weren't working properly on the right PCBs. The line was stopped after the first 20 units all had the same problem. After inspection, we realised the magnetic sensor wasn't the correct part! The magnetic sensor is a chip that detects if the keyboard is split or attached. Matt, our CTO, explained how this works in one of our Youtube videos.

The factory ordered a magnetic sensor with a different sensibility. Uh-oh. These magnetic sensors are so sensitive that even a small change in the position of the magnet will affect the connection of the keyboard. We developed a software to calibrate the sensor and our testing jig detected the problem.

The supplier is expressing that the correct sensor and the right-side PCBs will be assembled this coming week. If we hadn't caught this issue now, then we would have only found out about it at the final end of line test, which would have meant a lot of time wasted taking apart 2,000 keyboards and fixing 2,000 PCBs! Phew.

What learned from this:

This is a fine example of the importance of quality control. Initially, we were questioning how to fully test the boards. We've seen other keyboard test jigs that don't actually test, but just flash the firmware. A functional test is done at the end of the assembly line and they just cross their fingers that their PCBs are good.

Our tests are more thorough, but a lot slower than just flashing.

The factory tests one PCB at a time. We only have one test jig for the left main board and one for the right. That means they first test 2,000 left-side PCBs one by one manually, then another 2,000 right-side PCBs.

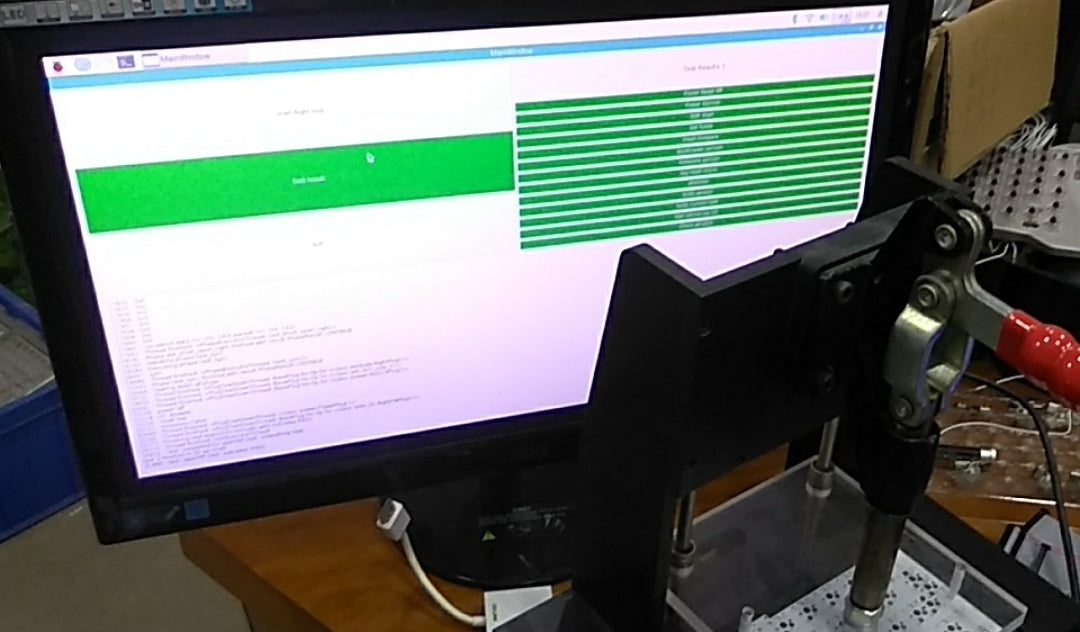

Testing and flashing the left main board

We weren't sure if this was really worth it because of how long it took. But after catching that issue with the magnetic sensor, we were given proof that a thorough quality control test, no matter how slow or long it takes, is always worth it in the long run.

White ABS Keycaps

The white ABS keycaps are made by a single-injection of translucent material, ABS (Acrylonitrile Butadiene Styrene) material. They are painted twice so that the light won’t shine through the entire keycap and just through the legend. They are painted in a grey color and then in white. After that, they are laser-etched and a layer of UV coating is applied for protection.

The first batch of white ABS keycaps from the DVT order didn’t have the quality we wanted. The white paint on the side of the keycap was poorly done.

And the backlight wasn’t bright enough. There was a black outline around the legends. This was because the first layer of paint was too dark.

In order to solve this, the factory changed the color of the first layer of paint to a lighter shade of grey and improved the general paint quality.

Neuron sticker

The Neuron sticker, found at the back of the Neuron, contains the serial number of the keyboard and other information.

We changed the material of the Neuron sticker because the serial number in the old one kept fading after some time. The contents of the new sticker are printed in the inner part so we can be sure that it won't fade.

Now we have two different finishings for the sticker, one for the silver Neuron and one for the black.

Configurator Software

We have a list of things to work on with the configurator software and we’re crossing off the fixes one at a time. Here are the things we've been working on:

1. Bug in ISO layout

We fixed this bug we found in the ISO layout. The key beside the left shift was missing. ISO layouts should have a small left shift and an extra key in between the left shift and the Z key, unlike ANSI layouts which have the left shift long like the one in the first image below.

ISO layout - with missing key beside left shift

We had it updated, added the key, and now the layout is correct.

2. Default layers of the Raise modified

We updated the default layers. The first default layer has a turquoise underglow and backlight keys. The keys with the same function have the same color, (space keys are green, backspace keys are blue, enter keys are yellow).

Layer 1

In the second default layer, you have the F keys at the top with purple backlights. The modifier keys and the special thumbkeys have the same function as the first layer. The keys with the “xxx” are keys with no function.

You have the Numpad on the right side and the arrow keys on both sides.

Layer 2

3. Macros

We are working on the macros feature but we don't have anything to show you as of yet! Hopefully, we'll be able to show it in the next update 🤞

4. Using the configurator software

Here’s a sneak peek of the configurator software where we demonstrate how to change key configuration, key color, and underglow

News about Shipping

Our logistics consultant confirmed with us that it would be better for us to first ship the keyboards to Spain and then to our EU customers. This only applies to the countries in the European Union. We want to avoid any problems that might arise in EU customs so we believe this is the best solution.

We’re nearly there guys!

Manel has already bought his ticket to China for October 10 and the assembly starts on the 14th. In our next update, we'll have news on the state of the assembly. Till then!

- Dygma Team