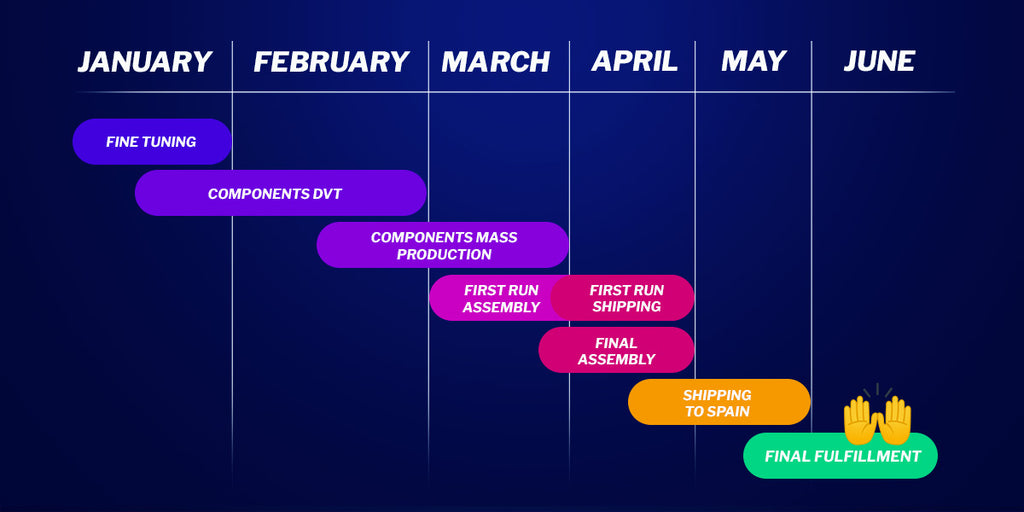

With the end of the Chinese New Year approaching, work is frantic at Dygma. We must be ready to launch all our components' DVTs as soon as they return from the holidays 🏖️

DVT stands for Design Validation Test, and it's a short production run of around 25 to 50 units of every component to spot issues that could surface on mass production.

Fortunately, we've made lots of progress, and almost everything is ready, just as planned. In fact, the electronics DVT is already being tested in our offices.

So, let's take a look at the status of every component 👀

Mechanical

Most of the mechanical components are ready to launch the DVT. The ones that take more time, like the transport case, the top panel, or the keycaps, will get started next week

We'll launch the rest of the components, like the palm pads, the bases, the cables, and the tenting legs, when Manel travels to China in the second week of February 🧳

We've made some last-minute improvements to some of them, and it's best if Manel is actually in the different factories overseeing everything and making adjustments.

One of these changes is the paint of the white tenting legs. The thing is that white needs more coats of paint than black. And the more coats you have, the higher the tolerance values you get. One leg is thicker, the next one thinner. That affects how the hinge and the inner tenting rods feel. They might be too tight or too loose.

We're making a larger batch to pinpoint that tolerance, but we might need to switch the paint from white to light gray, which requires fewer coats of paint, reducing the tolerance values.

Another change has to do with the larger reverse tilting leg. All the adjustments made to the other elements in the tenting solution –like the side legs now being trapezoidal– had made the reverse tilting wobble a bit.

Fortunately, making it 0.7 mm longer fixes the problem without affecting anything else, so with that, the paint, and some minor changes to the materials of the rods to make them more durable, the tenting parts will be ready to go ✅

We're thrilled with how the tenting solution has come together. It's so sleek yet highly sturdy. Under everyday use, it's just like typing with the keyboard flat against the table.

You only barely notice a flinch if you press really hard in the top inner-column keys, but that's a weird use-case scenario 😅

The other significant change is related to the base. Our supplier is redoing the mold to ensure that the slider that makes the holes for the hinges is consistent in larger batches.

We're also trying to eliminate the marks that the slider leaves on the base. You can barely see them, and they are pleasingly symmetrical, but we always aim for perfection 🤷♀️

Electronics

Finally, the DVT of the electronics arrived at our offices. We have 30 sets of keyscanner PCBs, 15 sets of underglow PCBs, 16 batteries, 25 wired Neuron PCBs, and 10 wireless Neuron PCBs.

With them on the table, we feel a bit like Tony Montana 😂

We had a minor setback on the RF PCBs, though. We couldn't get the SPI communication to work correctly, which drove us crazy. We thought it was the firmware, but it turns out one little trace was missing. Nevertheless, it's fixed, and they should be shipped next week 📦

In the meantime, we're testing all the other PCBs. We've already conducted a visual examination and tried a few sets, and we'll do the rest next week once we have a new version of the firmware that allows us to flash all the PCBs directly from the Neuron.

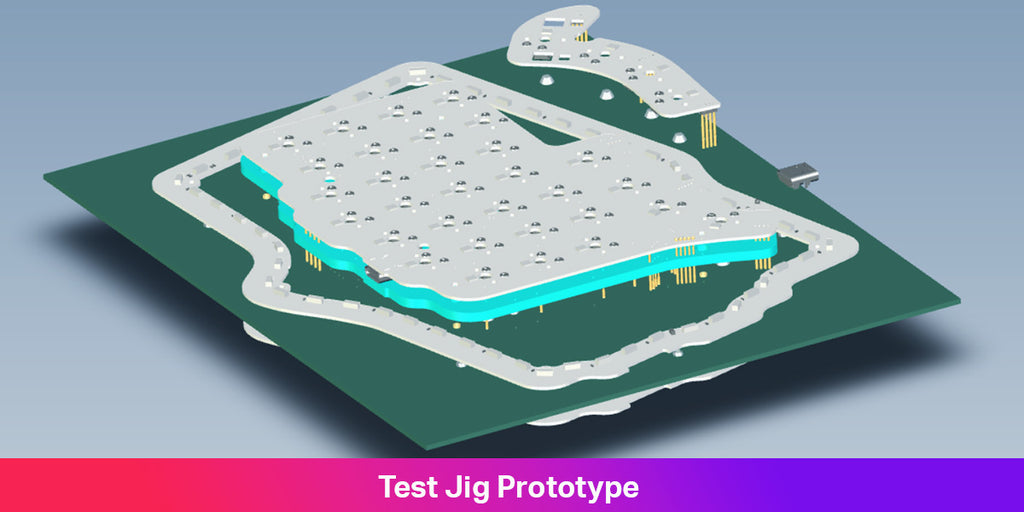

And talking about flashing, we're also working on the design of our test jig. It consists of a big PCB with many pins where you place the keyboard's PCBs.

This is then connected to a small device that automatically flashes and tests the PCBs. The factory will make an industrial version of ours, so the PCBs come out perfect 🤩

Once the DVT is green-lighted, we'll make a PVT (Production Validation Test) consisting of over a hundred sets of PCBs. Those will be used for the early-bird backers.

Firmware & software

Of course, the firmware team keeps working non-stop too. Right now, they are focused on being able to flash all the PCBs directly from the Neuron, but they are also working on improving the SPI communication for the wired Defy and on battery management.

The firmware is an unseen work, but it's critical. Nobody wants a beautiful keyboard if it's not working as it should 😅

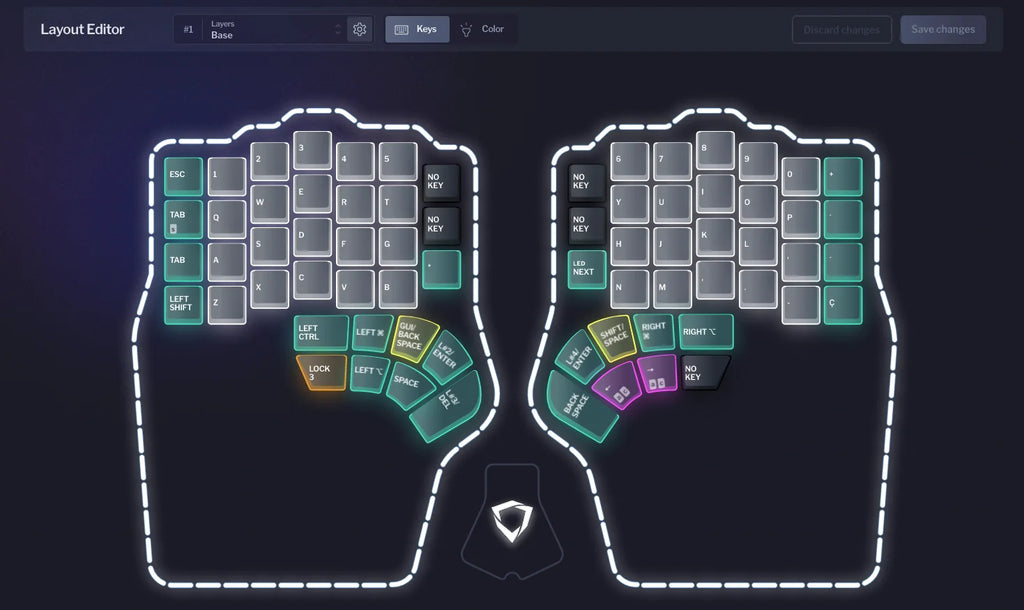

On the software side, we've started polishing our configurator software for the arrival of the Defy. As you know, Bazecor already works with the keyboard, but there are some bugs here and there that need addressing, and we also need to add all the wireless and battery management features 🔋

Bonus round 2: Live Q&A

We hold a Live Q&A on our Youtube channel now and then.

This is the last one, with timestamps in the descriptions of all the questions made.

If you don't want to miss the next one, don't forget to subscribe to our Youtube Channel 🔔

Bonus round 2: why is everything made in China?

In our last update, some of you asked an excellent question: why do we (and the rest of the world) make our products in China?

We thought it was worth making a video to answer it, so here it is 👇

And that's all for now!

Keep tuned for the next update; we'll report on everything that Manel will be doing in China!

Hanggang sa muli 🇵🇭