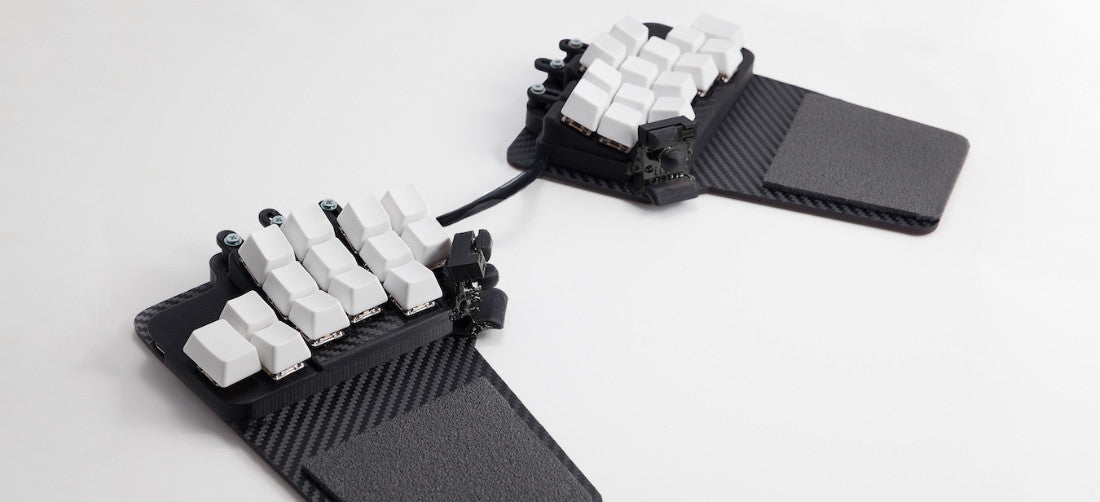

After many deliberations we decided to put the Shortcut aside (for now) and proceeded to develop a different keyboard: The Dygma Raise.

The Dygma Raise is an ergonomic keyboard designed to change the way we game and work. Unlike the Shortcut, we created it to be easy-to-use form the start.

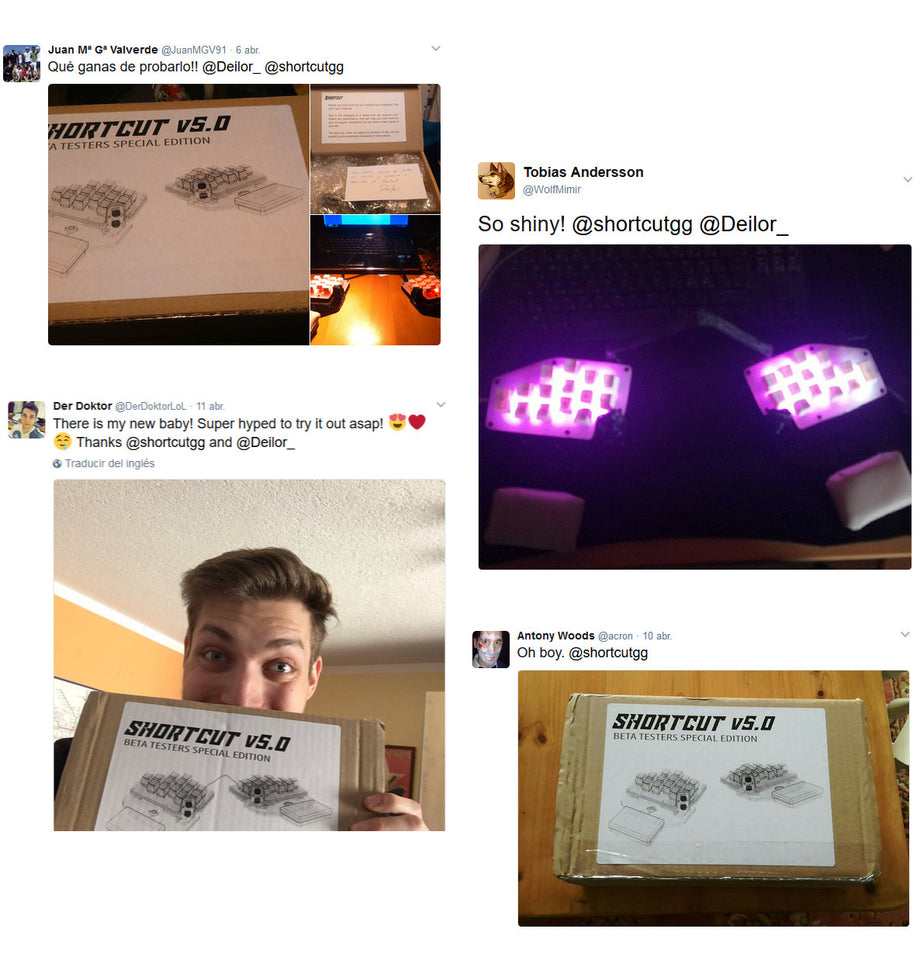

We thought it was a great idea, but we needed validation from the community. That was the first challenge.

In 2017, we launched a crowdfunding campaign on Kickstarter and it was a great success! Not only were we able to surpass our target but thanks to the feedback from our backers, we were able to improve the Raise even further.

That was only the beginning, though...